The commercial toothpick making machine is composed of a whole set of bamboo processing machines, therefore, the toothpick machine also named the toothpick production line or bamboo toothpick processing plant. The complete line for making high-quality bamboo toothpicks includes the sawing machine, stripping machine, bamboo sheets slicing machine, stick forming machine, stick set-size machine, toothpick chopping machine, toothpick polishing machine, toothpicks sharpening machine, toothpick packaging machine, etc.

Technical data of the toothpick production line

| NO. | Name | Model | Power(kw) | Weight(kg) | Size (mm) |

| 1 | Sawing machine (Bamboo) | SL-111 | 1.5 | 60 | 750*600*1300 |

| 2 | Stripping(dissection) machine | SL-102 | 3.0 | 530 | 3000*950*1200 |

| 3 | Bamboo sheets slicing machine | SL-103 | 3.0 | 260 | 1180*680*1100 |

| 4 | Stick forming machine | SL-104 | 9.1 | 400 | 1020*690*1050 |

| 5 | Stick sawing machine | SL-105 | 0.75 | 75 | 800*700*900 |

| 6 | Toothpick set-size machine | SL-114 | 2.57 | 140 | 900*700*950 |

| 7 | Toothpick polishing machine | SL-80 | 1.1 | 110 | 1050*1050*1200 |

| 8 | Toothpick sorting machine | SL-113 | 0.37 | 65 | 1050*900*850 |

| 9 | Toothpick sharpening machine | SL-268 | 1.65 | 160 | 950*650*1050 |

| 10 | Cutter sharpening machine | SL-108 | 0.37 | 50 | 450*400*870 |

Complete bamboo toothpicks processing craft

The main workflow for making bamboo toothpicks includes bamboo sawing(chopping)——bamboo dissection——bamboo sheets slicing——bamboo stick making——bamboo sticks bleaching and drying——bamboo sticks cutting——bamboo toothpick sizing——bamboo toothpick polishing——bamboo toothpicks sorting——bamboo toothpick sharpening—bamboo toothpicks packaging.

Components of the bamboo toothpick making machines

- Bamboo sawing/chopping machine

The first step for making bamboo toothpicks is to cut the dry bamboo stems into short sections by the bamboo sawing machine. This is the manual type of cutting equipment. The user can decide each of the chopping lengths of the bamboo sections. And the cutter plate of the machine is replaceable. When the knife edge becomes blunt, you can replace it with a new one, or you can remove the blunt knife and sharpen it with a cutter sharpener machine.

- Bamboo stem stripping machine

The second step is to slice the bamboo sections into bamboo sheets with the same width by the bamboo stripping machine. Each of these electric bamboo sheets making machine will be matched with 10 cutters for slicing the bamboo stems with different diameters. And it is very easy to exchange the cutter manually.

- Bamboo sheets slicing machine

The third step is to slice the bamboo sheets into thinner flakes by the automatic bamboo sheets slicing machine. The main purpose to slice the bamboo sheets is to remove the bamboo sheet skin and the inner bamboo joints and get the good bamboo materials for making toothpicks. It has high working efficiency for slicing the bamboo sheets with 60-80m per minute.

- Bamboo stick forming machine

The fourth step is to make bamboo sticks from the bamboo sheets by the bamboo stick forming machine. The electric bamboo sticks making machine can cut the bamboo sheets into cubic and round sticks very efficiently. And the diameter of the sticks can be adjusted by changing with the different cutting devices of this machine based on the users’ requirements.

- Bamboo stick sawing/chopper machine

Before this step for sawing the bamboo sticks, the users should bleach and dry these bamboo sticks before for making clean toothpicks. The main purpose of sawing the bamboo sticks is to make them shorter. The sticks chopping process is very easy and the cutting length can be adjusted manually.

- Toothpick set-size/sizing machine

The sixth step is to size the toothpicks by the automatic toothpick sizing machine. This set-size machine is mainly used to cut the bamboo sticks into the toothpick length efficiently. And the sizing length also is adjustable. Therefore, the users can decide their toothpick size when doing the toothpick production.

- Toothpick polishing machine

The seventh step is to polish the bamboo toothpicks by the toothpick polishing machine. This efficient polisher machine is suitable for polishing both of the wood toothpicks and the bamboo toothpicks. It is the batch type of polishing machine and each batch toothpick polishing only needs 3-5 minutes.

- Toothpick sorting machine

The eighth step is to sort these bamboo toothpicks by the automatic toothpick sorting machine. The main body of this sorting machine is also the wooden box with many small squares. Along with the continuous shaking, this machine can sort the toothpicks quickly. And then these sorted toothpicks can be further sharpened by the sharpening machine.

- Toothpick sharpening machine

The ninth step is to sharpen the bamboo toothpicks by the electric toothpick sharpening machine. This machine can sharpen both one end and two ends of the toothpicks with high efficiency. And it can process the toothpicks up to 1600 pieces per minute.

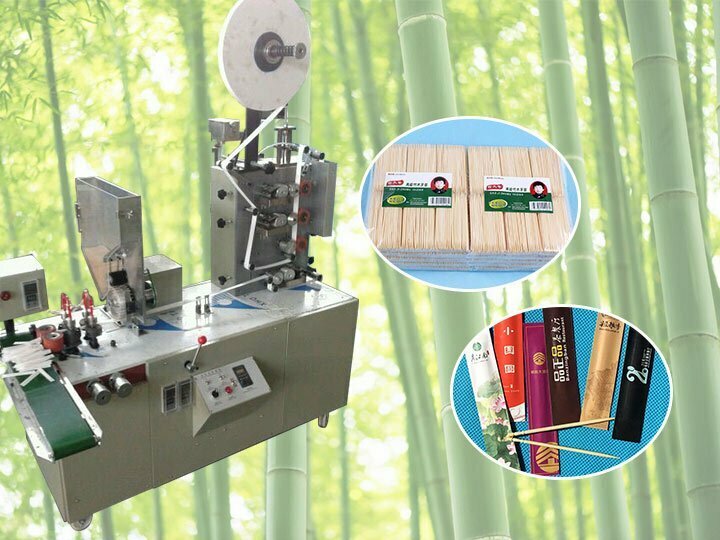

- Toothpick packaging machine

The last step is to pack the toothpicks into bags or bottles by the toothpick packaging machine. There are mainly two kinds of toothpick packaging machines in our toothpick machine factory. And the customers can choose the suitable type for packaging their toothpicks with separate bags or bottles.

bottle toothpick packaging machhine

bag toothpick packaging machine

- Automatic cutter sharpener

For most of the toothpick processing plants, this automatic cutter sharpener machine is very necessary for sharpening various cutters of the toothpick making machines.

Main features of the bamboo toothpick production plant line

- As the professional toothpick machine manufacturer in China, our toothpick production equipment has advanced technology and a reasonable price. The entire production line is highly automated. And the whole production line only needs 4-6 workers to complete the production of toothpicks.

- This whole set of toothpicks maker machines have the high working capacity, therefore, many toothpicks processing plants are in need of them for making great profits. The output of the entire set of toothpick processing equipment is: 800,000 toothpicks can be produced in 8 hours, with a total weight of 100 kg.

- The most common specifications for toothpicks produced by our customers are bamboo or wooden toothpicks with a diameter of 2mm and a length of 65mm. We can also customize toothpick production equipment of different specifications according to the specific needs of customers. The wearing parts of the entire automatic toothpick production line are forming knives, sizing blades, slicing cutters, diamond wheels, beef tendon belts, etc. We can provide all the details if you need for assisting your toothpicks production.