The large scale wood toothpick production line is composed of the whole set of toothpick machinery, which is a complete production process for making wooden toothpicks. How are toothpicks made? And to making wood toothpicks for commercial purposes? Here, we Shuliy toothpick machine manufacturer and supplier will share with you the overall knowledge of processing wood toothpicks in large quantities.

Detailed parameters of the wood toothpick making machines

| Name | Model | Power(kw) | Weight(kg) | Size (mm) | |

| 1 | Wood slicer machine | SL-656 | 6.05 | 260 | 1050*680*1050 |

| 2 | Sticks forming machine | SL-652 | 4.77 | 260 | 1050*680*1050 |

| 3 | Sticks cutting machine | SL-105 | 0.75 | 75 | 800*700*900 |

| 4 | Sticks sizing machine | SL-114 | 2.57 | 140 | 900*700*950 |

| 5 | Polishing machine | SL-80 | 1.1 | 110 | 1050*1050*1200 |

| 6 | Wood sticks sharpening machine | SL-113 | 0.37 | 65 | 1050*900*850 |

Brief introduction of the wood toothpick production line

To make wooden toothpicks can’t be done with just one or two machines. Starting from processing wood as a raw material to packaging finished wooden toothpicks, not only a set of toothpick processing machinery’s cooperation but also the tacit cooperation between processing workers.

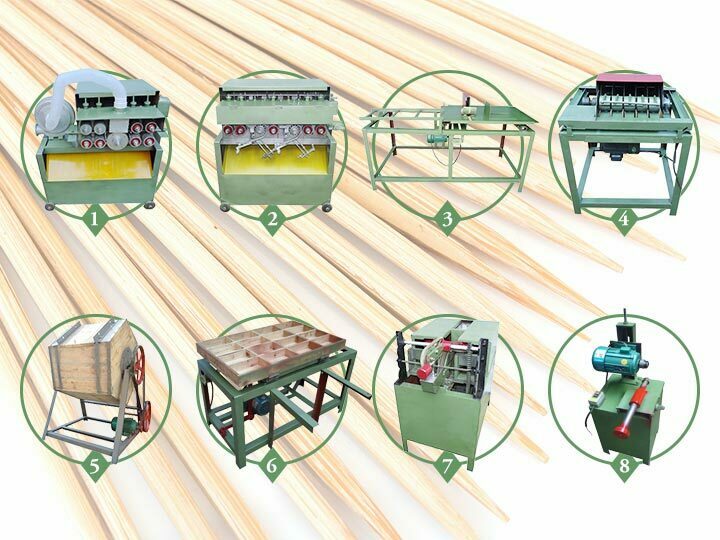

The wooden toothpick processing line is mainly composed of the following processes: wood cutting, wood blocks splitting, wood stick splitting, wood sticks chopping, wood sticks cut-to-length sawing, wood sticks polishing and sorting, wood sticks sharpening, toothpick packaging.

Main machines of the wooden toothpicks processing line

- Wood slicer machine

Before using the wood slicer machine, we need to split the logs used to make wooden toothpicks into pieces of about 10 cm thick first. When using this electric wood slicing machine, feed the wood blocks at one time into the machine’s feed port. A set of rolling cutters inside the slicer will soon divide the wood strips into uniform thickness wood sheets. These wood sheets are then processed into wood sticks in the next process.

- Wood sticks forming machine

The main function of the wood stick forming machine is to divide the wood sheets into smaller rods again. These sticks are the basic prototype of making wooden toothpicks. When using this wood stick cutting machine, put the wood sheets into the inlet of the machine one by one. Soon, these wood sheets will be cut into sticks with the same diameter. Customers can adjust the cutting device of the machine according to their actual production needs, and the diameter of the wood rod required for production.

- Wood sticks cutting machine

This wood stick cutting machine is the same machine as the bamboo stick sawing machine used in the bamboo toothpick production line. Because the main purpose of this cutting machine is to cut long rods into short rods of uniform length, the cut short rods can be further processed into toothpicks or BBQ sticks.

- Wood sticks sizing machine

The wood stick sizing machine is a machine that further shortens the wood stick. The machine is very efficient and can quickly cut wood sticks into short wood sticks of the same length (usually the toothpick length required by customers). Similarly, the cutting length of the machine is adjustable.

- Wood sticks polishing and sorting

The wood stick polishing machine and the bamboo stick polishing machine are also the same machine, mainly through the continuous rotation of the machine itself, the wooden sticks in the material box rub each other to achieve the effect of rapid deburring. After processing by this machine, the surface of the wooden sticks is smooth without burrs. After the polishing process, we will use wooden sticks sorting machine to automatically sort these sticks with the same placement position, which is convenient for the subsequent sharpening of the wooden sticks.

- Wood sticks sharpening machine

Wooden stick sharpening machine, also known as toothpick sharpening machine, is mainly used to sharpen wooden sticks and bamboo sticks. This machine is multifunctional and can not only sharpen one end, but also sharpen both ends, and it has a high degree of production automation, which is very practical for toothpick manufacturers.

- Wood toothpick packaging machine

Like packaging bamboo toothpicks, there are two types of machines for packaging wooden toothpicks. Toothpicks packaging machine and bottle toothpicks packaging machine. Customers can choose according to their actual needs, and we can also customize toothpick packaging machines according to customer requirements.

Outstanding features of wood toothpick machinery

- The output of this wooden toothpick production line is adjustable. We can recommend the appropriate machine model and output for customers according to the production scale and investment budget of their toothpicks production, minimize the waste of customers’ funds, and maximize the economic benefits of their investments.

- Many of the wood toothpick processing machines are the same machine as the bamboo toothpick production line, so if the customer wants to produce two kinds of toothpicks, only one or two additional machines can be purchased. In addition, customers can also use this machine to produce BBQ sticks, creating greater economic benefits.